|

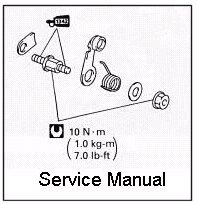

Again I refer to the service manual which

indicates that the nut holding the Stopper Comp spring

should be torqued to 7.0 ft-lb. So armed with my trusty

1/4" ratchet I proceed to remove that nut. Not gonna

happen. 7lbs with a 1/4" ratchet should be no problem.

I ended up getting a 3/8th ratchet and really had to put some torque on that nut, I'm guessing upwards of 20lbs or more. Enough I was getting concerned that I was going to break the stud off in the motor. Time for a cup of coffee to sit and think about this for a while. |

|

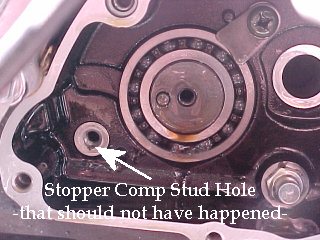

The coffee was good, so I decided to try one

more time. I said a couple of quick prayers and started

cranking on that nut again and it finally came loose

although not the nut, but the entire stud came out. No

big deal. I run to town to get a couple of metric nuts

that I can put on the other side so I can use two

wrenches to break the front nut. Not gonna happen. I worked on it for about 20 minutes, tried pinging it with a hammer to break any locktite, tried bracing one wrench on the ground, tried pretty much everything. Break out the big tools. I got a long 10mm wrench and the trusty 3/8th ratchet and took another crack. It was about then that I came to the conclusion I was going to break the stud before that nut came off. 7lbs my ass. |